AxialAltTech — power and efficiency in every move!

Welcome to the world of axial machine innovation! We are a team for whom the development and implementation of new technologies have become not just a mission, but a way and style of life.

Advantages

- Energy efficiency of 92–98%

- Reduced material consumption in production

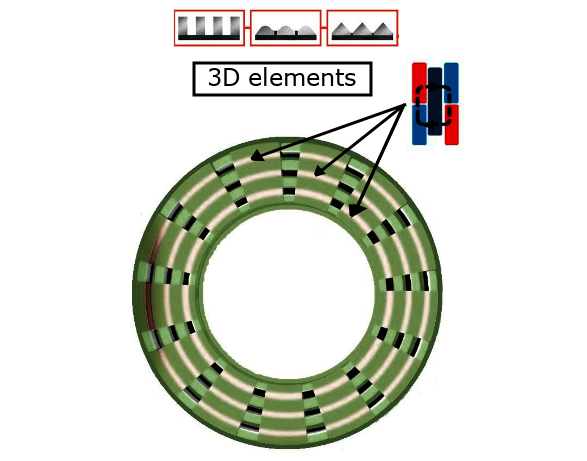

Increasing the Area of Magnetic Interaction

As It Is Now

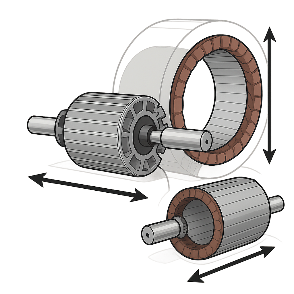

While many manufacturers are seeking optimal ways to increase the area of magnetic interaction between the rotor and stator for producing electric motors of various power levels and purposes, their approaches differ:

1. In radial electric motors, they typically increase the interaction area through simple scaling, which leads to excessive use of materials, increased size, weight, and production costs

2. In axial electric motors, they often use multiple rotors and stators on a single axis or add a radial interaction area to the axial one — creating so-called radialaxial electric motors

Our Advantage

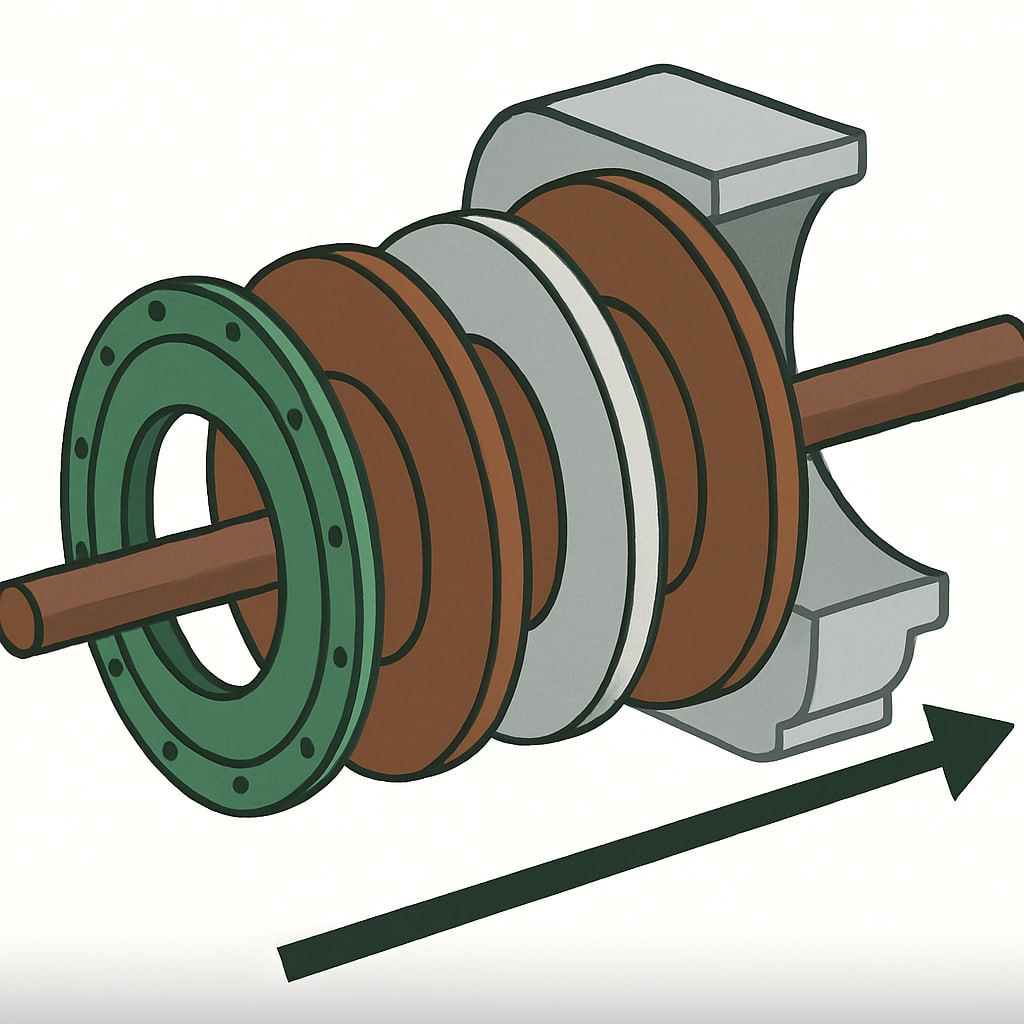

We have developed a unique technology that increases the area of magnetic interaction through three-dimensional expansion of the magnetic components on both the rotor and stator, oriented axially toward each other.

Achieving Minimal Vector Loads

As It Is Now

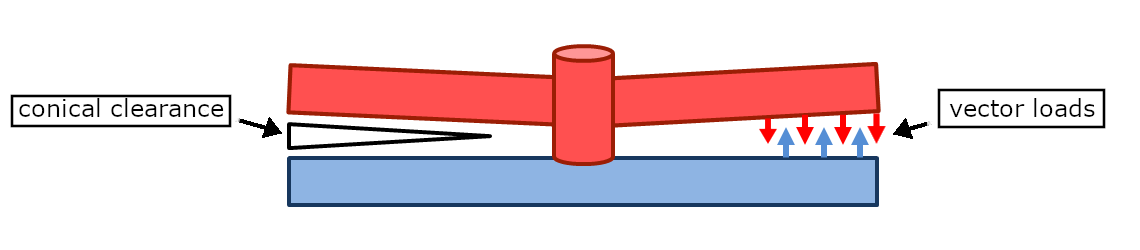

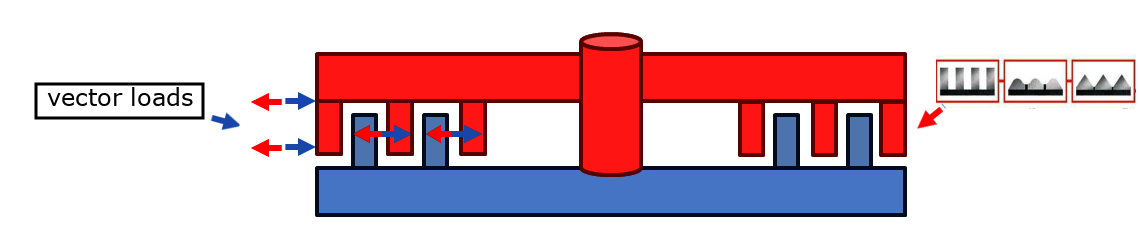

The higher the power of an electric motor, the more vibrations occur, and the larger the air gap becomes between the rotor and stator, which reduces both power output and efficiency. To address these issues, the motor design is typically made more complex — resulting in increased cost and weight.

Our Advantage

The applied KRP 3D technology enables the design of electric motors with minimal vector loads, which is not achievable with other technologies.

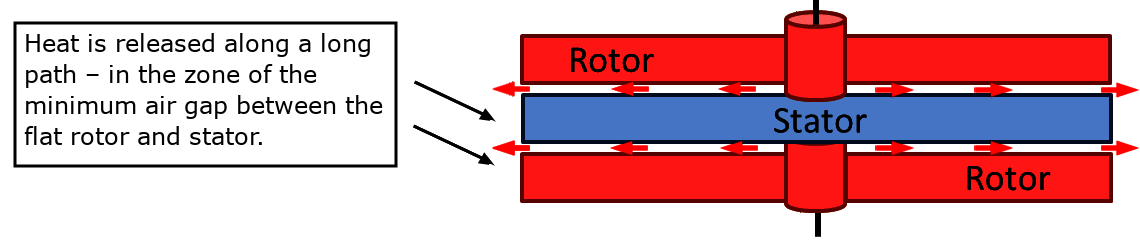

Optimal Heat Dissipation Along the Shortest Path

As It Is Now

Axial electric motors with flat rotors and stators have an architectural drawback: the stator is sandwiched between the rotors with minimal air gaps, making cooling difficult — air must travel a long path from the center to the outer radius.

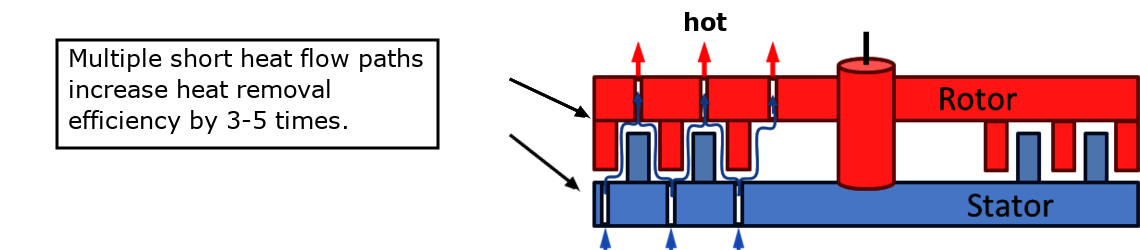

Our Advantage

In axial electric machines with 3D magnetic components, cooling airflow follows a much shorter path, improving heat dissipation by 3 to 5 times. Our technology also reduces heat generation in magnetic components by 30–35%, further simplifying the cooling process of the electric motor.

Eliminating Energy Losses

As It Is Now

Many axial electric motors suffer from a systemic flaw that leads to significant energy losses in the form of heat, reducing overall efficiency. Manufacturers often try to solve this by simply dissipating the heat into the environment. However, this doesn’t reduce the actual losses — on the contrary, excess energy turns into heat, increasing CO₂ emissions.

Our Advantage

To reduce energy losses and improve efficiency, we removed magnetic components from the central part of the motor. This led to a 30–35% reduction in heat losses and increased overall efficiency to 92–98%. We also patented optimal zones for placing 3D magnets, giving us a significant advantage over competitors.

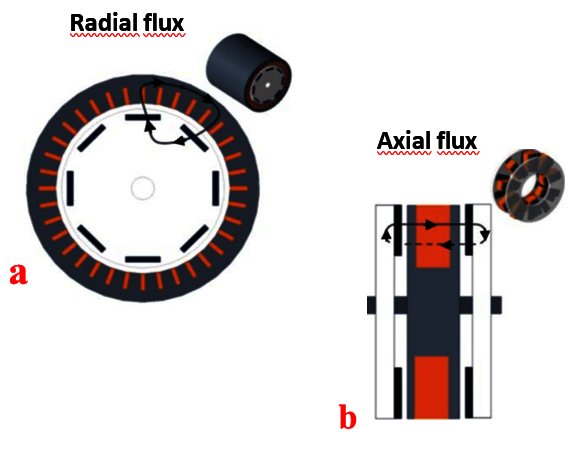

Advantages of a Shorter Magnetic Flux Path

As It Is Now

In axial machines without a yoke, the magnetic flux follows a shorter and more direct path compared to radial machines, where the flux bends through the rotor and stator. This gives axial machines clear advantages: torque is up to 3 times higher, power density is doubled, and weight and CO₂ emissions are reduced by 2–3 times. The benefits of axial technology over radial designs are evident. However, flat axial technology, despite its advantages, is limited by geometry: increasing power requires expanding magnetic components in 2D, which worsens the magnetic flux path.

Our Advantage

To improve the electromagnetic flow between rotor and stator, we applied a sectional design of 3D magnetic components. Our technology makes it possible to create magnetic sections with specific properties, using materials and solutions that are not feasible in conventional flat 2D architectures.

In our design philosophy for 3D axial machines, we have completely eliminated the use of a yoke in stator construction. This opens up the possibility of using grain-oriented electrical steel, which significantly reduces losses and enhances the magnetic properties of the motor. Previously, this type of steel was only used in transformers and could not be applied in radial electric motors.

The architecture of our KRP technology enables the use of new, innovative materials that further improve motor performance. These materials are incompatible with previous-generation electric motor designs, creating a significant technological gap.

Our technology also makes it possible to revolutionize the production of magnetic components by combining 3D soft magnetic composites (SMCs) with modern coil manufacturing methods, including 3D printing. This combination allows us to achieve:

- Lower overall mass

- Reduced manufacturing costs of magnetic components

- Higher magnetic flux density

- Increased power output with reduced motor weight

- Minimal hysteresis (remanence) losses

- Zero cogging torque

- Lower inductive losses

- Reduced thermal losses

- 30–50% less copper usage